Digital Twins: Transforming Smart Building Operations and Management

Explore how digital twin technology creates virtual replicas of physical buildings, enabling real-time monitoring, predictive maintenance, and data-driven decision making for facility managers.

Introduction

Digital twin technology is revolutionizing how we design, build, and operate smart buildings. By creating dynamic virtual replicas of physical assets, digital twins enable unprecedented visibility into building performance, predictive capabilities, and optimization opportunities that were previously impossible.

What Is a Digital Twin?

A digital twin is more than a 3D model—it's a living, data-connected virtual representation of a physical building that:

- Mirrors real-time conditions through continuous IoT sensor data feeds

- Maintains historical context for trend analysis and pattern recognition

- Enables simulation of various scenarios without impacting actual operations

- Provides actionable insights through advanced analytics and AI integration

The Digital Twin Ecosystem

A comprehensive building digital twin consists of several interconnected layers:

Data Layer

- IoT sensors (temperature, humidity, occupancy, air quality)

- Building management system (BMS) data

- Energy meters and sub-meters

- Access control and security systems

- Weather and external data feeds

Model Layer

- 3D geometric representation (often from BIM)

- Spatial relationships and asset locations

- System topology and connections

- Equipment specifications and parameters

Analytics Layer

- Real-time monitoring dashboards

- Anomaly detection algorithms

- Predictive maintenance models

- Energy optimization engines

Application Layer

- User interfaces for different stakeholders

- Integration with existing workflows

- Reporting and visualization tools

- Mobile and AR/VR access

Key Use Cases in Smart Buildings

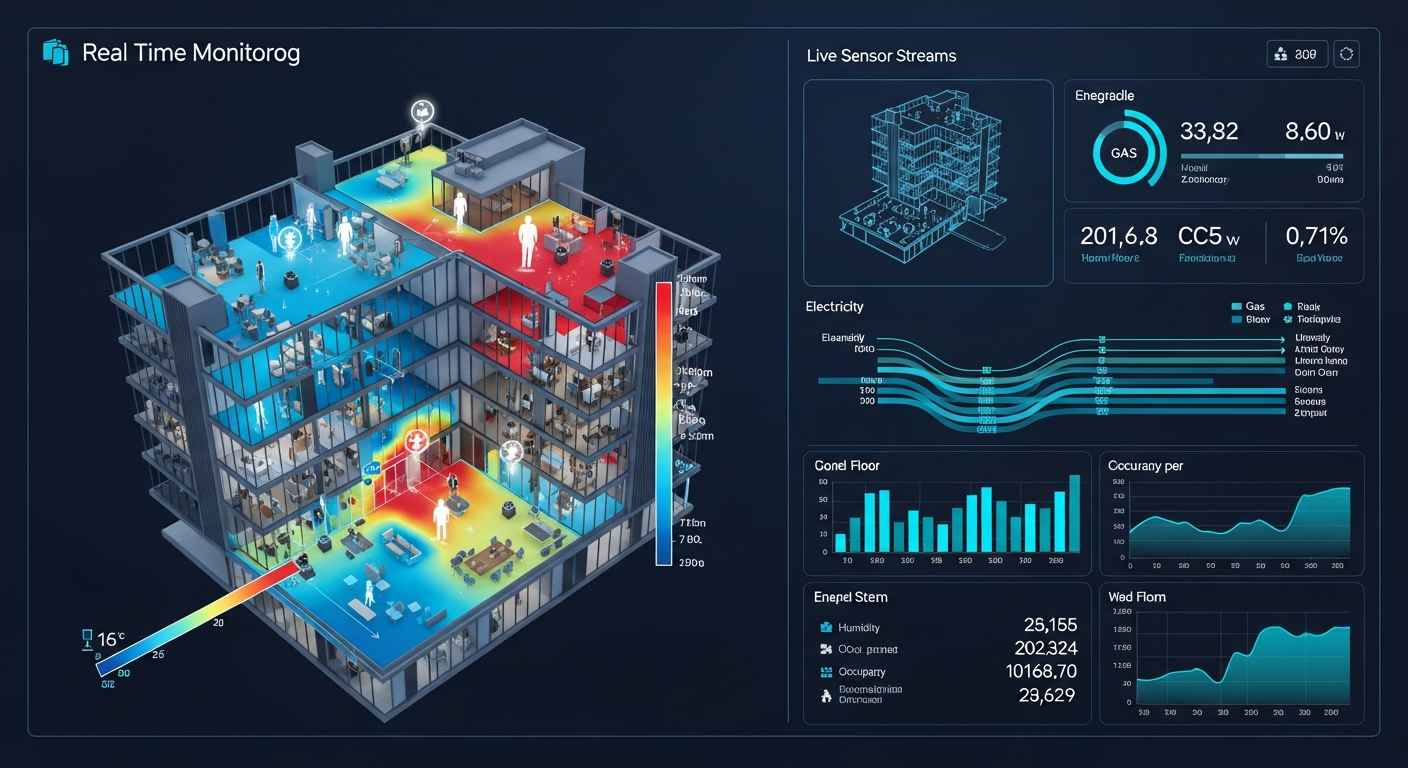

Real-Time Monitoring and Visualization

Digital twins provide intuitive visual access to building performance:

- Spatial context - See exactly where issues are occurring in the building

- Multi-system view - Understand relationships between HVAC, lighting, and other systems

- Occupant experience - Visualize comfort conditions across different zones

- Historical playback - Review past conditions to understand incidents

Predictive Maintenance

One of the highest-value applications of digital twins:

- Equipment health monitoring - Track vibration, temperature, and performance metrics

- Failure prediction - AI models identify equipment likely to fail before it does

- Maintenance optimization - Schedule repairs during low-occupancy periods

- Parts management - Predict spare parts needs before failures occur

Typical results: 25-40% reduction in unplanned downtime, 15-25% reduction in maintenance costs.

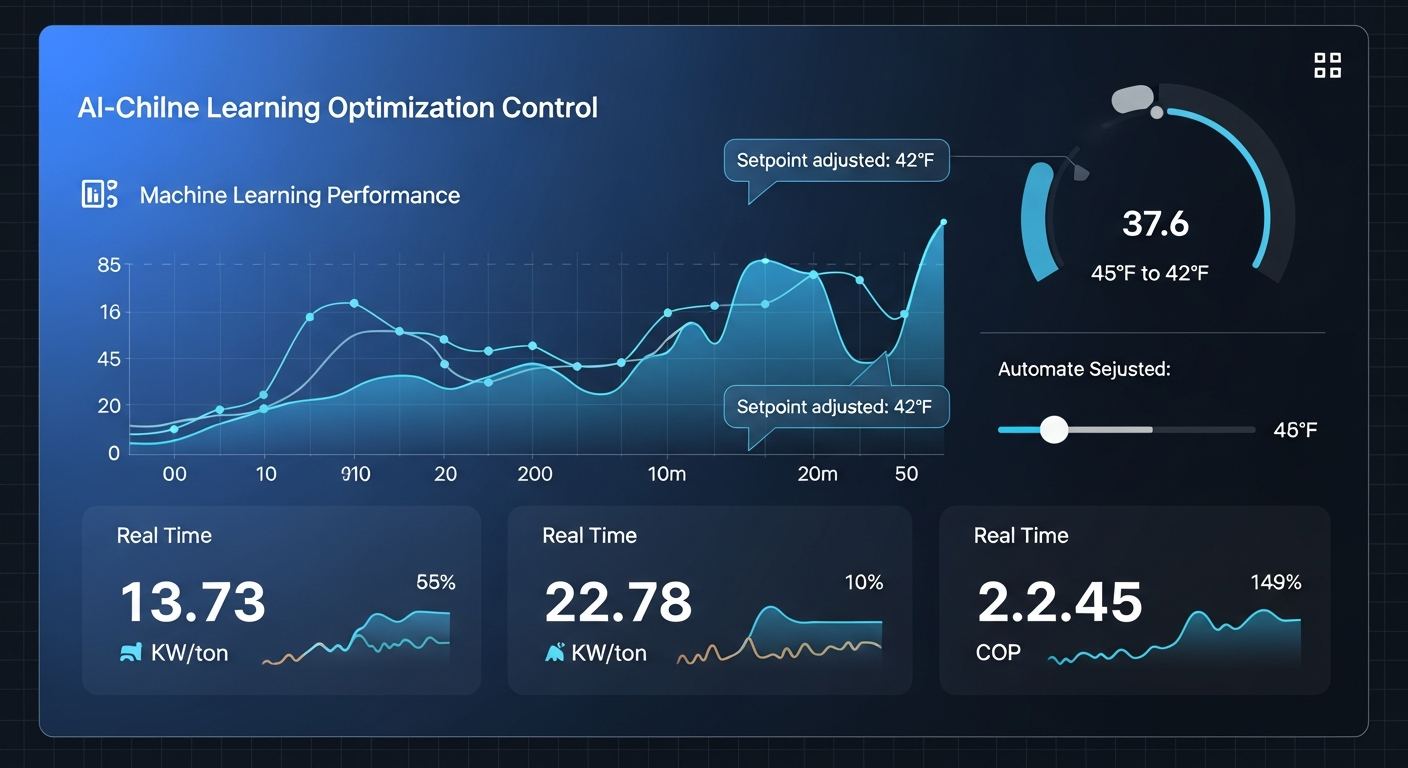

Energy Optimization

Digital twins enable sophisticated energy management:

- Load forecasting - Predict energy demand based on weather, occupancy, and schedules

- What-if analysis - Simulate impact of setpoint changes before implementation

- Demand response - Automatically curtail loads during peak pricing periods

- Renewable integration - Optimize timing of energy storage charging/discharging

Typical results: 15-30% reduction in energy costs.

Implementation Strategy

Phase 1: Foundation (3-6 months)

Data Infrastructure

- Audit existing sensors and data sources

- Identify gaps in monitoring coverage

- Implement data collection and storage platform

- Establish data quality processes

Initial Model

- Import or create 3D building model

- Map sensor locations to spatial model

- Configure basic visualization dashboards

- Train initial user group

Phase 2: Analytics (6-12 months)

Enhanced Monitoring

- Deploy additional sensors for complete coverage

- Integrate all building systems data

- Implement real-time alerting and notifications

- Develop system-specific dashboards

Phase 3: Optimization (12-18 months)

Advanced Features

- AI-powered optimization engines

- Scenario simulation capabilities

- Integration with maintenance management systems

- Mobile and AR access for field teams

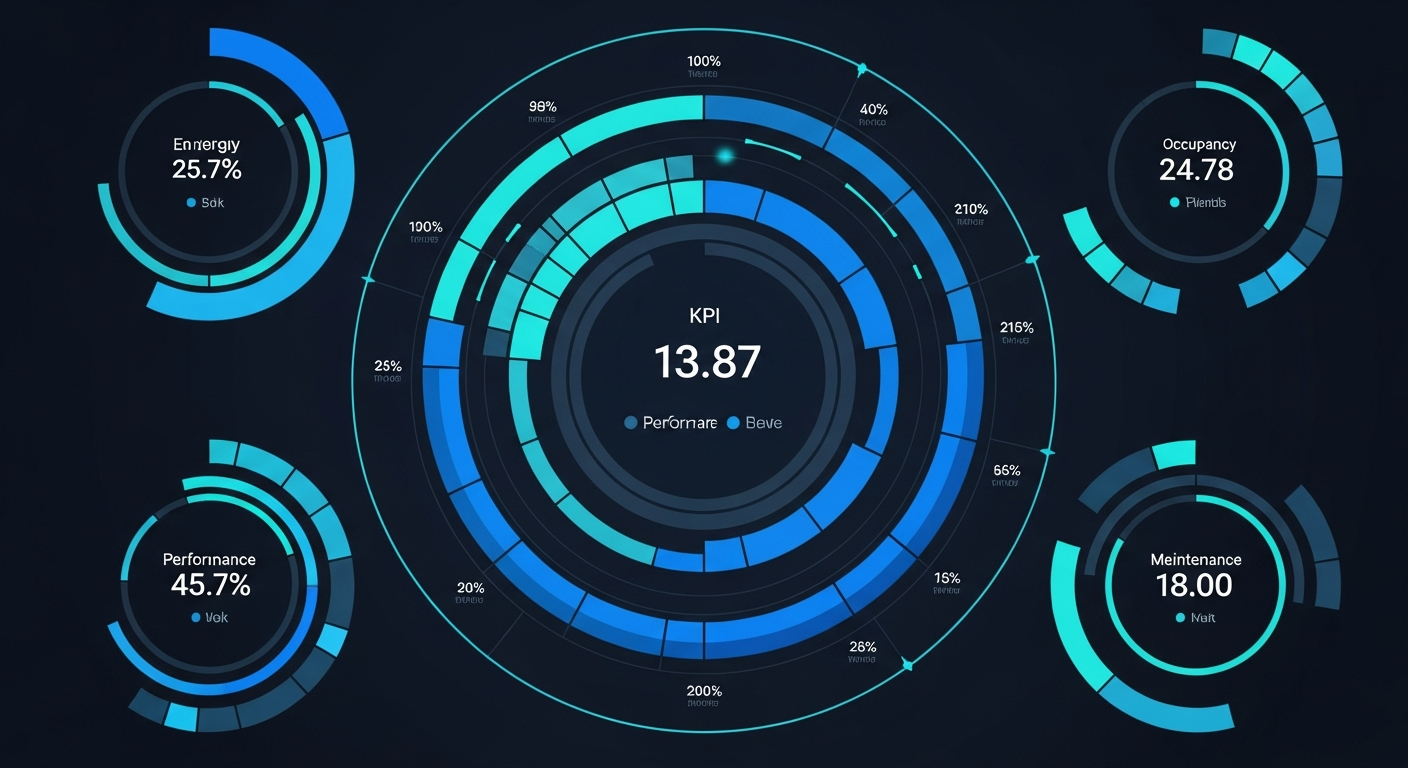

Measuring Success

Key Performance Indicators

Operational Metrics

- Equipment downtime reduction

- Mean time to repair improvement

- Energy consumption reduction

- Maintenance cost savings

Business Metrics

- Tenant satisfaction scores

- Space utilization rates

- Operating expense reduction

- Asset value improvement

ROI Expectations

Based on industry benchmarks:

- Year 1: 5-15% return through quick wins in energy and maintenance

- Year 2-3: 20-40% cumulative return as advanced capabilities mature

- Long-term: 3-5x return on investment over 5-year period

The CONTEXUS Approach

CONTEXUS provides the open-source foundation for building digital twins:

- Data integration layer - Connect any sensor, system, or data source

- Flexible visualization - Support for multiple 3D engines and interfaces

- Built-in analytics - Pre-configured models for common use cases

- Extensible architecture - Add custom capabilities as needed

- No vendor lock-in - Own your data and models

Conclusion

Digital twin technology represents a fundamental shift in how buildings are managed and optimized. By creating virtual replicas that mirror physical reality, facility managers gain unprecedented insight into building performance and powerful tools for prediction and optimization.

The technology is mature, the ROI is proven, and the competitive advantage for early adopters is significant. Organizations that invest in digital twin capabilities today will be better positioned to operate efficient, sustainable, and occupant-friendly buildings for decades to come.